|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| FORMBLOCK | Links | |||||||||||||

|

Metal moulds of series "FORMBLOCK"

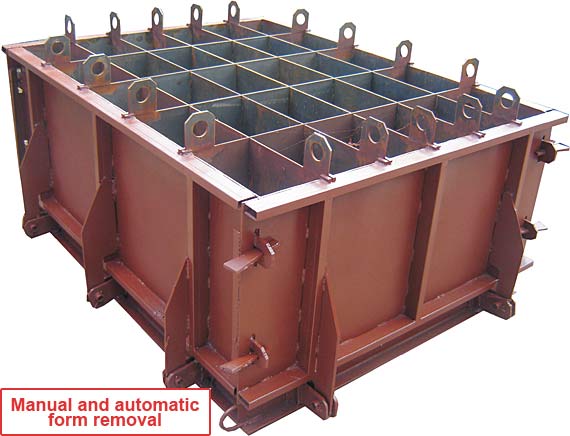

The moulds "FORMBLOCK" are distinguished by easy in assembly and disassembly, storage and transportation. The mold design allows to assemble and dissemble molds as in the production shops, as just on construction site. The mould includes lateral walls, a bottom and partitions. The boards are made from rigid tube of rectangular section and sheet metal of 4-5 mm by thickness. The bottom is welded from channel and sheet metal of 5 mm by thickness, has some stiffening ribs to provide smooth surface of bottom foundation that helps to mold articles without serious deviations. The walls are fixed to the bottom with reinforced hinges that make possible to assemble and disassemble moulds even after thousands of cycles operation. The partitions are made from sheet metal by thickness 4-5 mm by thickness (depending on the size of partitions) by means of plasma arc cutting machine of American companies

Mould drop sides are connected by quick locking fixing arms. The drop sides make the operation with mould easy and effective just in the conditions of strict saving of production areas. The mouls has maximum easy-to-use design, molds are easily assembled and disassembled and served by two workers and the resistance to external effects guarantees its operating life. The price of metal molds "FORMBLOCK" is much lower than the high accuracy molds, but the quality of ready products is differed a little. Competitive advantages of moulds of series "FORMBLOCK":

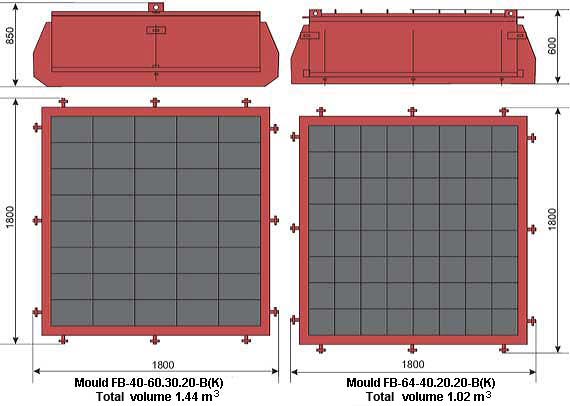

Types and overall dimensions of moulds "FORMBLOCK"

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 "Stroymachanika" LTD | Catalogue Dealers About us News Contacts Site map |

High accuracy moulds "FORMBLOCK" by the production of the engineering enterprise "Stroymechanika" are intended for molding of light-weight dimensional blocks (foam concrete, polystyrene concrete and etc.) and other materials.

High accuracy moulds "FORMBLOCK" by the production of the engineering enterprise "Stroymechanika" are intended for molding of light-weight dimensional blocks (foam concrete, polystyrene concrete and etc.) and other materials. and

and  .

.