|

24 February, 2014

Signing of contract for Albania

«StroyMehanika» LTD signed the contract with a company «ALART shpk», Albania.

More >>

December 5, 2013

Supply of equipment to Nigeria

"StroyMehanika" LTD signed the contract with a Nigerian company "KINGSDALE MULTI-RESOURCES LIMITED" for supply of machinery on "Sistrom" technology.

More >>

November 11, 2013

Sales contract for supply of equipment to Iraq

On November 8, 2013 the company "Stroymechanika" OOO signed the sales contract with company "ISOCRETE Factory" for supply of equipment for foam concrete, polystyrene concrete to Iraq.

More >>

|

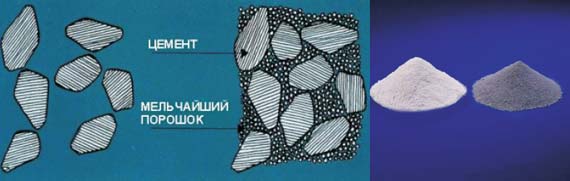

Microsilica is used as highly active mineral concrete and cement agent and intended to mix high-grade concrete by strength, water resistance and high rust-proof quality.

Microsilica is used as highly active mineral concrete and cement agent and intended to mix high-grade concrete by strength, water resistance and high rust-proof quality.