|

|

|

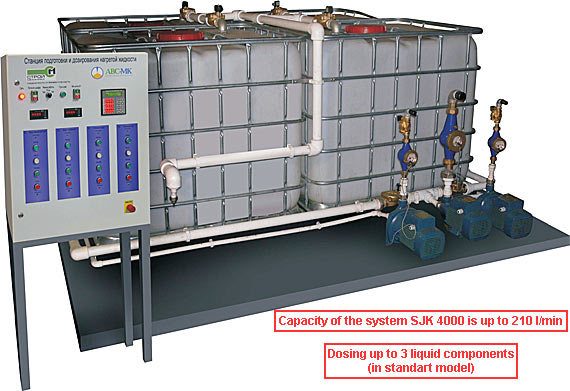

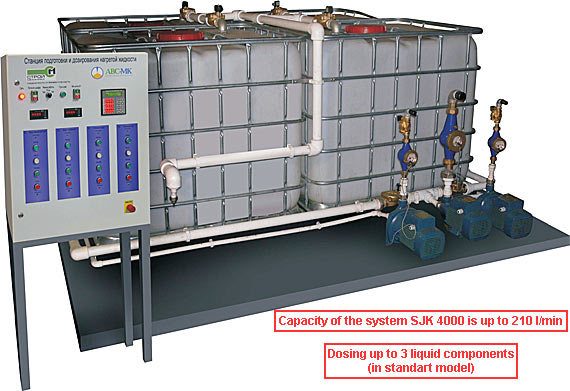

Preparing and batching system of liquid components SJK 4000

The preparing and batching system of liquid components SJK 4000 by the production of machine building company "Stroymechanika" is intended to prepare liquid mortars by method of circulation mixing, heating and maintenance of specified temperature of mortars, volumetric batching by continuous portion method and its next portion conveying through pipeline to the destination place. It is possible the mixing of three liquid components with dose of 1-999 liters at the same time using the SJK 4000. It is possible to enlarge the quantity of working mortars too. The preparing and batching system of liquid components SJK 4000 by the production of machine building company "Stroymechanika" is intended to prepare liquid mortars by method of circulation mixing, heating and maintenance of specified temperature of mortars, volumetric batching by continuous portion method and its next portion conveying through pipeline to the destination place. It is possible the mixing of three liquid components with dose of 1-999 liters at the same time using the SJK 4000. It is possible to enlarge the quantity of working mortars too.

The system SJK 4000 will be successfully used on enterprises of different branches of industry where the preparation and accurate batching of liquid mortars of set temperature is needed (including chemical agents solutions, dyes, foaming agents, and etc.)

Application of the system SJK 4000:

- Chemical industry: production of liquid agents.

- Production of paints and varnishes: production of water-dispersed paints, water-based priming, wood protective compounds.

- Construction: production of qualitative foam concrete mixes, qualitative polystyrene concrete mixes, concrete mixes, anticorrosion and protective compounds.

- Agriculture: production of working mortars, herbicides, combined fertilizers.

- Food industry (in special performance): production of carbonated beverage, alcoholic beverage products, juices, fruits and vegetables.

|

The system of preparation and batching of liquid components SJK 4000 includes a metal foundation, plastic tanks (4 pieces), batching and conveying block, box of automated control system SAU SJC LOGIC.

Description of operation of the system SJK 4000 by the way of example of production of foam concrete mix components:

Water through system of pipelines in the specified sequence is filled in plastic capacities of the station. The concentrate of foaming agent and required water are filled in the tank for solution of foaming agent, in capacity for a solution of the chemical additives, necessary additives and also necessary quantity of water is filled in. Liquid components (foaming agents and chemical agents) are mixed by means of circulating pumps built into the lateral wall of the tank, heated to the set temperature by means of heating elements, and supplied in concrete mixer or other devices in a sequential order. Water is also heated up to the set temperature by means of heating elements, and is supplied in concrete mixer in in a sequential order.

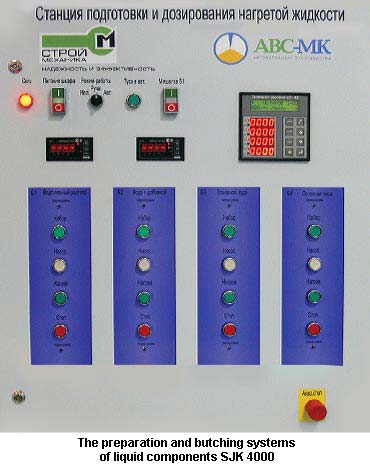

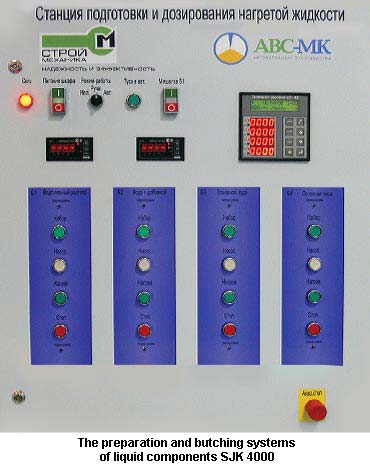

The control by the batching and preparing system for liquid components SJK 4000 is made from the front panel of the box of automated control system SAU SJK LOGIC. The batching and preparing system for liquid components SJK 4000 operates in both manual and automatic control mode. There is a terminal for external connection on the frame of eth box in order to connect with external automatic control system. The control by the batching and preparing system for liquid components SJK 4000 is made from the front panel of the box of automated control system SAU SJK LOGIC. The batching and preparing system for liquid components SJK 4000 operates in both manual and automatic control mode. There is a terminal for external connection on the frame of eth box in order to connect with external automatic control system.

The required temperature and doses (in litres) for each components are programmed from the front panel of the box of automated control system SAU SJK LOGIC. The programmed volume of ready mortar is conveyed through pipeline in concrete mixer after pressing the button "START".

For operation in industrial complexes of series "StroyFoamConcrete" intended for foam concrete production, the preparation and batching system of liquid components, equipped with the foam generator TRITON 5М, and also with pneumatic system intended for supply of compressed air in the pipeline of the foam generator is recommended for use. The applied foam generator TRITON 5М works on any types of foaming as in both automatic and manual mode. For operation in industrial complexes of series "StroyFoamConcrete" intended for foam concrete production, the preparation and batching system of liquid components, equipped with the foam generator TRITON 5М, and also with pneumatic system intended for supply of compressed air in the pipeline of the foam generator is recommended for use. The applied foam generator TRITON 5М works on any types of foaming as in both automatic and manual mode.

It is recommended to fill the tank of the system with preheated water no lower than 10°С in order to support the capacity and to save electric power.

The preparation and batching systems of liquid components SJK 4000 can be used for modernization of existing foam concrete production lines, and also the complete equipment of recreated industrial complexes or plants. The system of preparation and batching of liquid components SJK 4000 showed itself to good advantage in operation with mixing complex of series "HYACINTH" atomized complexes "StroyFoamConcrete" - foam concrete production, as well automized complexes "StroyPolyConcrete" - polystyrene concrete production.

The preparation of water and solutions influences deeply the quality and of ready products at mixing of foam concrete mix, polystyrene concrete mix, concrete and building mortars.

The application of the prepared liquid components allows to save the expensive materials used at manufacturing of products. The preparation and batching systems of liquid components SJK 4000 are used on concrete plants and production areas where the application of the prepared liquid components and mortars is required, in those productions where the administration takes care of the production of high-quality products.

Competitive advantages of the preparation and batching systems of liquid components SJK 4000: Competitive advantages of the preparation and batching systems of liquid components SJK 4000:

- Capacity up to 210 liters per minute allows to apply the system SJK 4000 in both as a part of small production complexes and highly-productive automated lines.

- Compact dimensions of the construction allows to apply the system SJK 4000 in both as a part of stationary production complexes and mobile installations (e.g. as a part of mobile concrete plant of series "MOBILBETON").

- The operation with all types of concrete mixers and mortar mixers makes the system SJK 4000 universal in application.

- Foam generator TRITON 5М, used as a part of the system SJK 4000, operates both on synthetic and organic foaming agent that helps to produce more qualitative foam concrete with application of organic foaming agent.

- High quality of montage of the system SJK 4000 allows to use the installation for a long time without breakages.

- Integration in automated complexes became possible thanks to application of automated control system SAU SJK LOGIC developed by our partner - "ABC-MK" company (Russia).

The application of qualitative components of European manufacturers influences the safe and stable operation of the foam generator:

- water meter of

company (WEHRLE, Germany); company (WEHRLE, Germany);

- electromagnetic valves of

company (ASCO JOCOMATIC, Netherlands); company (ASCO JOCOMATIC, Netherlands);

- circulating pumps of

company (PEDROLLO, Italy); company (PEDROLLO, Italy);

- level detector of

company (OVEN, Russia); company (OVEN, Russia);

- logical controllers of

company (AVS-MK, Russia). company (AVS-MK, Russia).

Composition of the preparation and batching system SJK 4000

| Designation |

Quantity |

Note |

| Frame-foundation |

1 ps. |

Overall dimensions 2500×2100×100 mm |

| Tank of operating mortar |

4 ps. |

Volume 1 m³ |

| Centrifugal pump |

1 ps. |

RK-300:

capacity 150 l/min,

rated capacity 2,2 kW |

| Centrifugal pump |

2 ps. |

SR-170:

capacity 30 l/min,

rated capacity 2,2 kW |

| Fluid flow meter |

|

Impulsive |

| Electromagnetic valve |

8 ps. |

Solenoid,

supply voltage 220 V |

| Check valve |

|

|

| Fluid level probe up/down |

8 ps. |

Type: conductometric |

| Temperature probe |

4 ps. |

Resistive temperature transducer |

| Heating element |

12 ps. |

Rated capacity 12 kW |

| Automatic control system SAU SJK LOGIC (control box) |

1 ps. |

Overall dimensions 800×300×1000 mm |

| Pipeline |

20 m |

|

Optional equipment

| Designation |

Quantity |

| Foam generator TRITON 5М |

1 |

| Compressed air block |

1 |

| Air compressor К11 |

1 |

Technical characteristics

| Quantity of tanks, ps. |

4 |

| Volume of tank, l |

1000 |

Rated capacity , kW

- with application of source of water heating

- without application of source of water heating |

86

50 |

| Supply voltage, V |

380 |

| Frequency, Hz |

50 |

| Maximum liquid dose per cycle, l |

999,9 |

| Minimal water dose per cycle, l |

1 |

| Relative batching error, % |

2,5 |

Water pressure in pipeline MPa (kgc/cm)

- max

- min |

1,0 (10)

0,3 (3) |

| Temperature of mortars, °C |

5-45 |

| Error of support of preset temperature, % |

5 |

| Overall dimensions (L×W×H), mm |

2500×2100×1165 |

| Weight of the unit, kg |

400 |

| Flow control limits , l |

1 |

Maximum capacity of one component, l /min

- water

- agent |

150

30 |

| Maximum quantity of cycles |

999 |

Overall dimensions

The composition of the preparation and batching system of liquid components SJK 4000

1. Frame-foundation; 2. Tank of operating mortar; З. Centrifugal pump (mortar conveying №1); 4. Centrifugal pump (water supply); 5. Centrifugal pump (mortar conveying №2); 6. Consumption meter (mortar №1); 7. Consumption meter (water); 8. Consumption meter (mortar №2); 9. Fluid level counter (up/down); 10. Temperature probe; 11. Heating element; 12. Circulating pump (mixing of mortar components); 13. Electromagnetic valve (water supply in tank of operating mortar); 14. Electromagnetic valve (mortar conveying №1); 15. Electromagnetic valve (water supply); 16. Electromagnetic valve (mortar conveying №2).

|

|

The preparing and batching system of liquid components SJK 4000 by the production of machine building company "Stroymechanika" is intended to prepare liquid mortars by method of circulation mixing, heating and maintenance of specified temperature of mortars, volumetric batching by continuous portion method and its next portion conveying through pipeline to the destination place. It is possible the mixing of three liquid components with dose of 1-999 liters at the same time using the SJK 4000. It is possible to enlarge the quantity of working mortars too.

The preparing and batching system of liquid components SJK 4000 by the production of machine building company "Stroymechanika" is intended to prepare liquid mortars by method of circulation mixing, heating and maintenance of specified temperature of mortars, volumetric batching by continuous portion method and its next portion conveying through pipeline to the destination place. It is possible the mixing of three liquid components with dose of 1-999 liters at the same time using the SJK 4000. It is possible to enlarge the quantity of working mortars too. The control by the batching and preparing system for liquid components SJK 4000 is made from the front panel of the box of automated control system SAU SJK LOGIC. The batching and preparing system for liquid components SJK 4000 operates in both manual and automatic control mode. There is a terminal for external connection on the frame of eth box in order to connect with external automatic control system.

The control by the batching and preparing system for liquid components SJK 4000 is made from the front panel of the box of automated control system SAU SJK LOGIC. The batching and preparing system for liquid components SJK 4000 operates in both manual and automatic control mode. There is a terminal for external connection on the frame of eth box in order to connect with external automatic control system. For operation in industrial complexes of series "StroyFoamConcrete" intended for foam concrete production, the preparation and batching system of liquid components, equipped with the foam generator TRITON 5М, and also with pneumatic system intended for supply of compressed air in the pipeline of the foam generator is recommended for use. The applied foam generator TRITON 5М works on any types of foaming as in both automatic and manual mode.

For operation in industrial complexes of series "StroyFoamConcrete" intended for foam concrete production, the preparation and batching system of liquid components, equipped with the foam generator TRITON 5М, and also with pneumatic system intended for supply of compressed air in the pipeline of the foam generator is recommended for use. The applied foam generator TRITON 5М works on any types of foaming as in both automatic and manual mode. Competitive advantages of the preparation and batching systems of liquid components SJK 4000:

Competitive advantages of the preparation and batching systems of liquid components SJK 4000:

company (WEHRLE, Germany);

company (WEHRLE, Germany); company (ASCO JOCOMATIC, Netherlands);

company (ASCO JOCOMATIC, Netherlands); company (PEDROLLO, Italy);

company (PEDROLLO, Italy); company (OVEN, Russia);

company (OVEN, Russia); company (AVS-MK, Russia).

company (AVS-MK, Russia).